- Horn Type : Hyperbolic (T=0.7) Constant Directivity (CD) horn

- Coverage : H 95°, V 40°

- Cut-off frequency (Fc) : 290Hz

- Frequency range : 540/600Hz to 20KHz

- Driver : 2"in throat like TAD 4001/4002, JBL 2446/2450 or 1.4" driver with adapter

- Size : W 656mm, H 230mm, D 405mm (inclu. 25mm throat adapter)

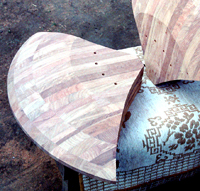

- Material : Chinese quince laminated lumbers (3.0cm thickness)

- Finish : Two coats of oil based clear polyurethane varnish

- Four fins (separators) inside the horn

Drawing files:

Yuichi recommend to use drawing file for re-draw your own at 1:1 scale on a hard paper as a construction template.

These templates are very important to make accurate horn curves or contours.

For now it's the original PDF, as see in Horn Design section some information is not strictly exact :

A290 PDF

There is a easier version to build of the A290, the 290S :

A290S PDF

It's not really interesting to build this against the regular A290 but it highlights the fact that the sides are just another fin, because in this version it's truly the case.

Building:

http://www.cinetips.com/viewtopic.php?f=40&t=698

Yuichi Arai original content:

| Transfer template on a laminated lumber by pencil. | Cutting of the lumber by hand circular saw |

Addition of both wings | Application of glue by fixing wings |

||||

| Completion of coarse formation process | Adjustment of side curve of the plates |

Verification of side curve alignment among three |

Application of epoxy glue (12 Hrs to cure) |

||||

| Lamination of three horn plates by fixing clamps and four screws |

Obtain vertical contour by a electric plane |

Fine adjustment by a rotary sander and a belt sander or sandpaper |

Completion of top and bottom horn pieces |

||||

| Gaining thickness of the side horn walls |

Contour making of the side walls of the horn |

Completion of internal fins Belt sander may be used. |

Location of four fins Epoxy glue is applied. |

||||

| Side walls are assembled with epoxy and screws. |

Final assembly and filling process by epoxy and wood powder mixture |

Driver adapter (circle - square converter) Epoxy coating inside |

Surface treatment by a hand router, a rotary sander and sandpaper |

Measurement:

Left hand data is frequency response curve. TAD 4001, 2 in throat, driver is mounted. The response shows very flat sound pressure level from 350Hz to almost 20KHz. This horn with 2" driver covers mid to high frequency range in 2 way or 3 way construction. However, very high frequency response depends upon the driver capability. To set the crossover frequency as 300 to 400Hz is a little risky. Therefore, 600Hz above is safe to use.

Directivity coherence with 15" is around 650hz.